Description

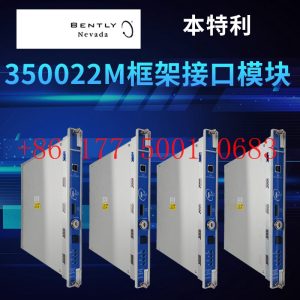

330180-91-05 Framework interface module

330180-91-05 Framework interface module

Module Clips Drive controller servo motor

Contact: Mr. Lai

Wechat:17750010683

Whats app:+86 17750010683

Skype:+86 17750010683

QQ: 3221366881

3221366881@qq.com

Overview 330180-91-05 Framework interface module

Trendmaster Pro is an innovative online vibration monitoring system that links hundreds of permanently mounted transducers and measurement points to a single-cable sensor network. It then transmits full-waveform & spectrum data to our System 1 software, with its intuitive interface for tracking, alerting & analyzing your machinery behavior.

This online condition monitoring system is optimized for cost-effective monitoring of machines of intermediate criticality, i.e. machines that don’t demand immediate shut-down protection, but for which monthly portables-based monitoring would be insufficient. A highlight of this system is its suitability for use in the most hazardous environments (i.e. explosive gases).

A wide range of sensor types are supported, including vibration (Acceleration, Velocity, Displacement), temperature (RTD & K thermocouple), Pressure, Process Variables (20mA, 5V), Rack Buffered outputs. Each Transducer Interface Module provides 2 channels of measurement.vbOnline Pro: Online Vibration Monitor

Monitor machinery with rolling element bearings and complex gear trains utilizing our 12-channel sampling system.Overview

Our superb vbOnline† Pro was designed to monitor the condition of machinery with rolling element bearings and complex gear trains. The plantwide condition monitoring system is built to monitor vibrations via a system of 12-channel sampling. They can differentiate the vibration signals as acceleration, velocity, and more.

Some available features are two tachometer channels, which monitor using keyphasors, laser or optical TTL sensors, and other pulse-based speed sensors, and an allowance of trending variables through the System 1 † machine condition monitoring software.

All of vbOnline Pro is fully supported by System 1 software, which can connect the vbOnline to almost any other condition monitoring systems you may have installed in your plant.

Major global oil & gas producer improves speed, quality, and cost of maintenance builds

PROBLEM 330180-91-05 Framework interface module

A super-major oil and gas producer’s capital-project maintenance builds were costing too much and taking too long using a traditional maintenance-build approach, and the resulting maintenance strategies were of poor quality. The company was experiencing continual overspending, missed deadlines, and maintenance strategies that didn’t deliver the performance and reliability the operations team needed from the asset base. The company needed to find a way to decrease expenditures and increase delivery speed, while completing the highest-quality capital projects in terms of maintenance and reliability.

The company needed:

risk-justified equipment-reliability strategies based on the operating context of that region or country’s assets that met the specified operational performance targets;

equipment-reliability strategies to comply with regional regulatory requirements; and

digital equipment-reliability strategies, to allow for improvement modifications based on available data.

Additionally, the company wasn’t retaining intellectual property following maintenance builds – the contractors kept it – so the company couldn’t leverage data from one capital project to the next. They were also plagued with inconsistent and poorly structured Master Data, due to the disconnected nature of the maintenance-build projects.

SOLUTION

The oil and gas producer chose ARMS Reliability and its OnePM-powered Asset Strategy Management (ASM) approach to complete their capital-project maintenance builds moving forward. ARMS provided a technical solution that halved the costs associated with maintenance builds and significantly simplified the process of completing them.

The OnePM® approach provided a single environment in which to complete maintenance builds, streamlining file management and eliminating the need for unstructured applications like Excel. Team members no longer had to deal with the inefficiencies, errors, and confusion that inevitably arose around multiple files, versions, and file locations shared among multiple team members.

OnePM® also substantially reduced the number of contractors necessary to complete maintenance builds, and created a full client-specific maintenance build library, leveraging their existing operations equipment-strategy library to offer operational context and to utilize their current best asset strategies. Additionally, ARMS provided technical-reliability-engineering support as necessary –at a dramatically lower rate than the previous contractor-heavy support model.

ARMS worked with the client to pilot its ASM approach on a large Capex production unit floating in the Gulf of Mexico. Based upon the initial project’s positive results, OnePM® was ultimately rolled out to the client’s whole capital-projects portfolio of 5-10 major projects running simultaneously around the globe.

Beginning with the company’s equipment list and classes, Bill of Materials, and OEM manuals, ARMS Reliability used its OnePM® platform to give the company new and better ways to build and manage maintenance strategies:

Building with New Approach

Create asset master data

Determine criticality

Deploy central strategy

Incorporate region-wide variations

Incorporate local variations for operating context

Package tasks and generate preventive maintenance [PM] master data, using predefined auto-packaging rules

Generate budgets, and labor and spares forecasts

Load to SAP via formatted integration links

Digital maintenance strategies are dynamically applied to an asset structure, accounting for asset criticality, make and model, and duty. This process ensures consistent, quality-assured, compliant master data, ready for deployment to SAP. The process supports regional or local variations to accommodate different operational or environmental conditions, all while maintaining the connection to the digital strategy knowledge base.

Managing Strategies in Operations with New Approach

This new maintenance-build approach creates an improved link between delivering capital-project maintenance strategy and turning the assets over to regional operations to manage. Operations can now use the following process to keep asset strategies dynamic and continuously improving:

Monitor dashboard of maintenance-strategy effectiveness

Issues or incidents trigger and perform RCA or strategy review

Workflow review and approval for recommended strategy changes to relevant stakeholders

Update local, regional, and corporate strategies, as necessary

Deploy all changes

Update PM master data

Load change to SAP and monitor performance

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts