Description

106M1079-01 Framework interface module

106M1079-01 Framework interface module

Module Clips Drive controller servo motor

Contact: Mr. Lai

Wechat:17750010683

Whats app:+86 17750010683

Skype:+86 17750010683

QQ: 3221366881

3221366881@qq.com

List Graph

Improving efficiency

The ARMS Reliability approach provides customers with a way to ensure efficient and consistent maintenance builds, integration with SAP, and centralized asset strategy management. With the help of new tools, the company’s efficiency in developing maintenance strategies has increased by 5-10 times compared to before, saving manpower, time, and ultimately money through more reliable asset base performance.

List Graph

Higher quality 106M1079-01 Framework interface module

Using OnePM ® Supported ASM methods enable customers to now view the entire maintenance build process and monitor the quality of maintenance strategies in real-time. The new system allows companies to use built-in QA/QC checks to view and modify data throughout the entire maintenance build process, rather than waiting until the project is completed to review the quality of the maintenance build.

List Graph

Easier governance

The new ASM method includes automatic quality assurance data checking and automatic packaging for successful loading into SAP. These features help ensure maintenance of build and data consistency, multi-level progress reporting, and easy maintenance strategy review and change approval.

List Graph

intellectual property right

The work of ARMS Reliability means that customers can now retain their maintenance and construction intellectual property – easily leverage improvements by deploying them across all relevant assets and projects, and continuously improve their maintenance strategies over time – while linking maintenance and construction with customer performance requirements.

System 1 Asset Health Management Software

Why do we need to conduct asset health monitoring?

The success of any process intensive industry largely depends on the appropriate maintenance and management of work power machinery. Unplanned downtime or inefficient maintenance routines can reduce productivity and erode your profits.

image

New logo HMI_ Plantside

At Bentley Nevada, we understand the challenges customers face. Our System 1 † software is designed to provide you with an integrated solution to address the most challenging challenges of machine asset management and operational monitoring. The System 1 platform is built on the strategic pillars of connectivity, analysis, and visualization, providing the key asset monitoring data and analysis solutions you need throughout the factory to maintain smooth operation and avoid unnecessary downtime.

The interconnection platform of System 1 collects and stores the important machine Health data of the entire enterprise in a central location for real-time analysis, diagnosis and status based Preventive maintenance planning. Use System 1 to make data-based decisions and achieve true operational intelligence.

Explore the advanced rule construction and data mapping functions, decision support of System 1

Bentley Customer Service

Bently Nevada’s customer service provides support to customers throughout the entire business lifecycle.

Quotation: Customer data maintenance, quotation generation, and initial part number classification and support

Ordering: PO review and acceptance, order reservation

Order management: Status of existing orders, change orders, and tracking information

Bentley Technical Support

The Bentley Nevada technical support team provides customers with technical information related to products, documentation, knowledge, and training. Whether you hold basic, basic, or advanced M&S protocols or SSAs, our technical support team can provide customized support capabilities and information. This team provides services to every customer of our Bently Nevada asset status monitoring product.

Nowadays, many of our clients focus on comprehensive management of their production assets. Our clients know that assets in modern industrial facilities are not limited to rotating machinery. That’s why we designed System 1 for more than just mechanical management

-Orbital Magazine, 2001

Reading the introduction above, you may think that this is Bentley Nevada’s recent introduction about the System 1 platform. However, this statement was made approximately 20 years ago during the launch of System 1. Twenty years ago, Bentley Nevada redefined the asset management space, and at that time, we envisioned and delivered a software platform for overall asset monitoring with the necessary visualization capabilities to support connection, analysis, identification, and diagnosis of asset health.

Over the past 20 years, System 1 has been an important tool for oil and gas, power generation, and general industrial customers, with over 10000 active users worldwide. In addition, our service team utilizes this platform to provide 24/7 real-time remote asset monitoring and expert mechanical analysis support to end customers. At Bently, we are very proud of the tradition and continuous development of this product to meet new use cases and solve new customer problems.

This article will provide an overview of the evolution of System 1 (from Classic to Evo) and preview the future development of this asset management platform.

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

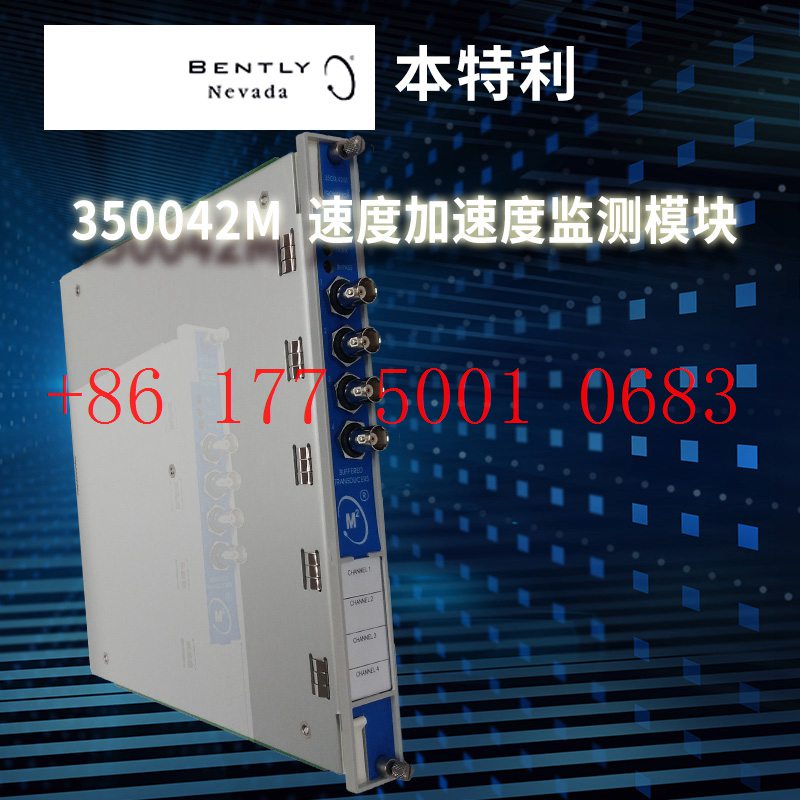

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts