Description

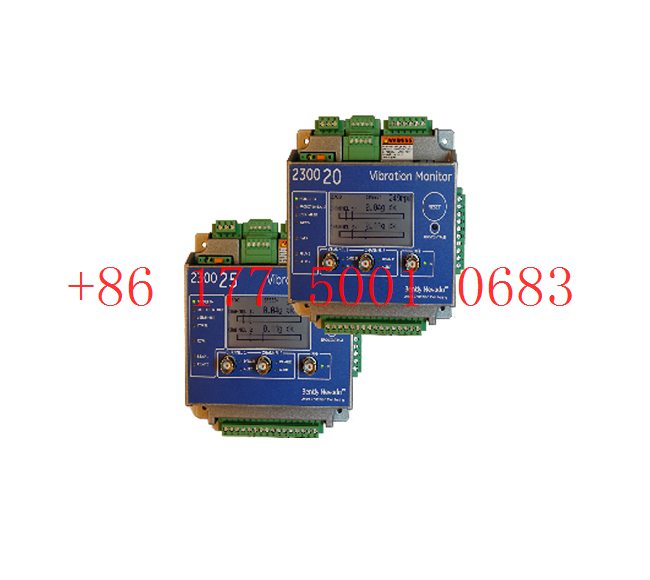

3500/05-01-01-00-00-01 Mechanical protection system

3500/05-01-01-00-00-01 Mechanical protection system

Module Clips Drive controller servo motor

Contact: Mr. Lai

Wechat:17750010683

Whats app:+86 17750010683

Skype:+86 17750010683

QQ: 3221366881

3221366881@qq.com

A large number of oil and gas production operations are carried out manually, resulting in low efficiency, safety risks, and the possibility of increased emissions.

Leucipa’s automated on-site production solution enables on-site production automation, eliminating or significantly reducing these issues

Due to its implementation of on-site production automation, operators are able to proactively manage on-site production.

The Leucipa automated on-site production solution is different from any other production optimization solution because:

It is built by operators and serves them. Leucipa’s automated on-site production solution is supported by detailed industry and customer research to identify problems, define solutions, and drive their design

It provides a personalized experience, providing reliable and feasible suggestions to meet the respective on-site priorities of each operator

It combines key professional knowledge and is developed in collaboration with industry recognized experts in the fields of cloud and industrial data conversion

It is open, fast, and scalable, compatible with any system and independent of OEM, easy to deploy and understand, and scalable to adapt to constantly changing business needs

Energy and industry executives have stated that technology availability is the most important factor in accelerating their energy transformation strategy, but they are also concerned about its risks. What would encourage them to invest?

Society faces the three challenges of energy: we need to access safe, sustainable, and affordable energy. To address this issue, we need to expand and diversify low-carbon energy sources, which means expanding new and mature power generation methods, fuels, and decarbonization technologies.

Baker Hughes conducted an annual energy transition pulse survey of 555 energy and industrial business leaders in 21 countries. The latest research found that the availability of technology has become the most important factor to accelerate the energy transition.

Improving energy efficiency through existing infrastructure or validated upgrades can become a quick way for companies to reduce carbon emissions. But to truly play a role, energy and industry need to focus on deploying more decarbonization technologies. Financing and supply chain restrictions after the epidemic have posed obstacles, while reducing the risks of new technologies and large-scale infrastructure remains a challenge for many enterprises.

The emergence of technology is too slow 3500/05-01-01-00-00-01 Mechanical protection system

The International Energy Agency (IEA) said, “Some emerging technologies have made encouraging progress, but these positive trends need to be accelerated rapidly in the current decade to achieve the deployment level of achieving a net zero emission trajectory by 2050.” [1]

The key to accelerating this process is new value chains – such as carbon capture, utilization and storage (CCUS) – and new ecosystems around Alternative fuel, such as waste to energy and hydrogen.

Ilham Kadri, CEO and Chairman of the Executive Committee of Solvay, has successfully commercialized a new waste based power generation value chain to replace coal from two of his European factories. He stated that these new ecosystems are a win-win situation for Solvais. Stakeholders.

More usage will reduce costs

The commercialization of technology is an important component of expanding its use. As technology and fuel use become increasingly widespread, their costs will decrease, thereby stimulating greater demand.

This is what has happened to solar and wind energy in the past decade. Between 2010 and 2019, global solar photovoltaic costs decreased by 82%. [2] The IRENA cost study found that continuous technological improvement and larger economies of scale have played a role in deflation by reducing manufacturing costs.

Meg O’Neill, CEO of Woodside Energy, reviewed how continuous investments in renewable energy sources such as wind and solar have reduced deployment costs over time, and predicted that similar things will need to happen with new low-carbon energy and technology, as well as energy carriers such as hydrogen.

She said, “Technology is crucial for starting to reduce the cost of factors required for energy transformation.” “In the past few decades, we have seen a sharp decline in the cost of solar panels. Now we need to apply technology to ensure that other energy transformation opportunities also have cost competitiveness

Mark Nielsen, Executive Vice President of Strategy, Policy and Development of Chevron Corporation, said that more work needs to be done before hydrogen energy and others can make greater contributions to decarbonization. We need more technological development to help reduce manufacturing and transportation costs, “he said. We are still striving to achieve economies of scale, which will help with the transportation of hydrogen

What hinders investment in transformational technologies?

Baker Hughes’s survey found that technological risks combined with a bleak economic outlook are hindering investment in the energy transition.

Economic uncertainty, technological risks, and financing are the three major obstacles to investing in energy transformation technologies

What are the three major obstacles or challenges for your organization to invest in energy transformation technology?

How to encourage businesses to take action

The company will seek guarantees from pioneers, but these pioneers will hope to gain some sense of security and return on investment in new fuels, decarbonization technology, and infrastructure. Off take agreements, new partnerships, and targeted policy support are three ways to reduce technological risks and incentivize investment.

Off take agreement

The off take agreement reduces the financial risks of large-scale infrastructure projects for both producers and buyers: funding is guaranteed, market and supply are guaranteed, and pricing structure is fixed.

Lorenzo Simonelli, Chairman and CEO of Baker Hughes, said that the new business model is crucial to expanding the scale of liquefied natural gas (LNG) infrastructure. There are a lot of available resources, but we need to establish the correct financing mechanism, “he said. For example, liquefied natural gas off take agreements typically last for 20 years, but some companies only need to supply for five years. We need new and flexible business models to make progress on the project

New partnerships

For hydrogen and CCUS, partnerships and cross departmental collaboration will create new ecosystems to help monetize the decarbonization process. For example, the Bayou Bend carbon capture and storage project is the result of cooperation between Chevron Corporation, Talos Energy and CarbonVert. This project was announced in May 2022 and will become the first such project in the United States to sequester carbon from industrial facilities. [3]

“We are bringing together technology companies, infrastructure companies and emission companies to create the center,” said Mark Nelson of Chevron Corporation. You must constantly advance technology, gather the right people together, and require policy support to accelerate progress

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts