Description

3500/45 176449-04 Mechanical protection system

3500/45 176449-04 Mechanical protection system

Module Clips Drive controller servo motor

Contact: Mr. Lai

Wechat:17750010683

Whats app:+86 17750010683

Skype:+86 17750010683

QQ: 3221366881

3221366881@qq.com

Advantages of Bentley Nevada Factory Reliability Solutions

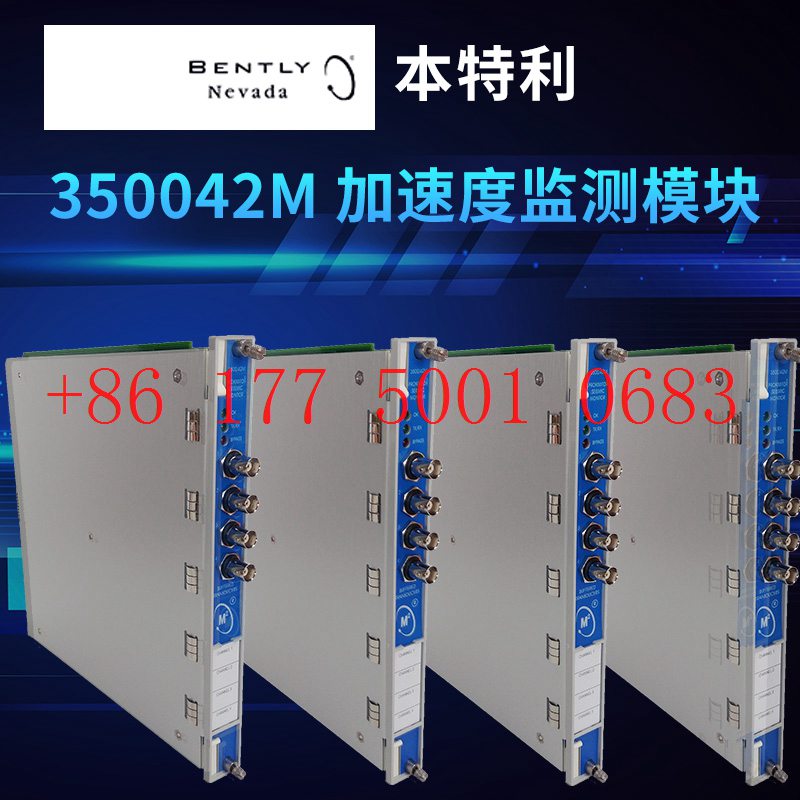

image 3500/45 176449-04 Mechanical protection system

Status monitoring of the liquefied natural gas industry

Narrowing the gap between reliability “goals” and the actual results achieved from current efforts typically involves three key impact areas:

Process: Our comprehensive service helps customers evaluate their goals, identify reliability gaps in current operations, and then implement appropriate corrective measures.

Tool: The Bentley Nevada product line is renowned for its unparalleled quality in mechanical condition monitoring. Everything necessary to address the assets used in liquefied natural gas factories is available, from sensors to continuous monitoring systems, to wireless sensor systems, to portable data collectors and analyzers. Moreover, all of these are concentrated in a unified asset status monitoring and diagnostic platform – Bently Nevada”s System 1 † software. We also assist customers in integrating and using their installed tools, such as computer maintenance management systems (CMMS) and reliability software.

Personnel: Reliability is not just about technology and processes. Even with the use of state-of-the-art tools and effective strategies, companies may not be able to achieve their reliability goals unless they are able to successfully change their way of working. Reliability is a company wide effort that involves operations, maintenance, planning and scheduling, procurement, management, and engineering. Bently Nevada can help customers change their work methods, transform factory operations, and reach new heights in process quality by addressing organizational culture issues that have led the company into ineffective processes.

Due to Bentley Nevada being able to completely solve every one of these problems, we are able to solve the entire problem, not just scattered problems.

Status monitoring of the pulp and paper industry

Your business is facing challenges.

In the increasingly competitive business environment, there are many things that you cannot control, such as the cost of wood, processed chemicals, and energy. What you can largely control is the safe and reliable operation of your production through Bently Nevada”s factory wide condition monitoring program. For over 60 years, Bentley Nevada has been a trusted partner in the industry. We understand your processes and mechanical assets. Let us help you create a status monitoring plan that suits your goals and budget.

Bentley Nevada Complete Portfolio

System 1 status monitoring software

Webinar: How to reduce downtime and improve productivity

With Bentley Nevada”s extensive product and service portfolio, you can achieve your productivity goals.

Pulp and Paper Monitoring Solutions

When implementing a new reliability plan, you must address three issues:

Process: For over 60 years, Bentley Nevada has been helping customers evaluate their goals, identify reliability gaps in current operations, and then implement appropriate corrective measures and strategies to maintain smooth operations.

Tool: Our Bentley Nevada product line is renowned for its unparalleled quality in mechanical condition monitoring. Everything necessary to address water and wastewater treatment plant assets is available, from sensors to continuous monitoring systems, to wireless sensor systems, to portable data collectors and analyzers. Moreover, all of these are integrated into a unified asset status monitoring and diagnostic platform – Bently Nevada”s System 1 software. We also assist customers in integrating and using their installed tools, such as computer maintenance management systems (CMMS) and reliability software.

Personnel: Reliability is not just about technology and processes. Even with the most advanced tools and effective strategies, companies may not be able to achieve their reliability goals unless they are able to successfully change their way of working. Reliability is a company wide effort that involves operations, maintenance, planning and scheduling, procurement, management, and engineering. Bently Nevada can help customers change their way of working, help them change their business and balance sheet by addressing the organizational culture issues that keep the company stuck in ineffective processes.

Maintenance: Hidden profit sources in pulp and paper manufacturing

Dynamic and active condition monitoring methods can extend uptime, optimize productivity and achieve Profit maximization

The pulp and paper business must strategically use maintenance as a continuous improvement process to better optimize manufacturing and increase profits. For this reason, leading manufacturers have only one choice: to adopt intelligent state monitoring and planning functions, and permanently and proactively optimize operations. This is the next important step for the development and survival of pulp and paper. This article is an excellent way to take the next step.

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts