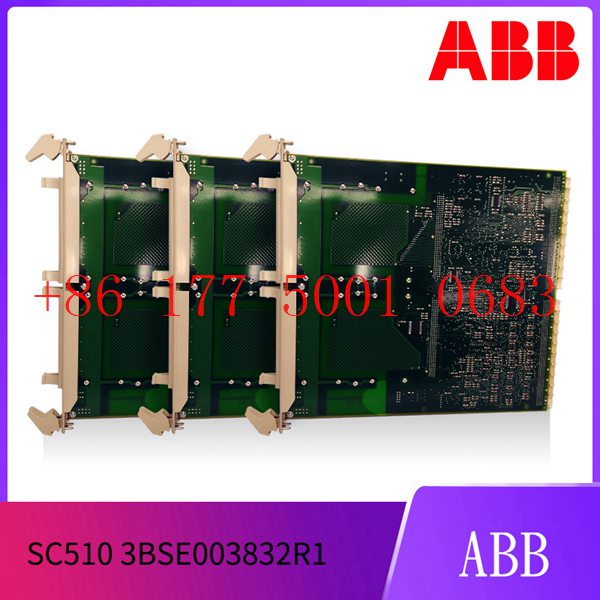

Description

3HAC055437-004 DCS system

3HAC055437-004 DCS system

Module Clips Drive controller servo motor

Contact: Mr. Lai

Wechat:17750010683

Whats app:+86 17750010683

Skype:+86 17750010683

QQ: 3221366881

3221366881@qq.com

3. Improper operation and adjustment during operation:

(1) The oil quality management is poor, the oil is of inferior quality or with different grades when it is imported, and it is not tested and put into the main oil tank for operation when it is received. Moreover, the maintenance quality is poor, the shaft seal clearance adjustment is not within the standard range, and the adjustment is improper. The shaft seal pressure is adjusted too high during operation, and the steam leaks to the oil stop, causing water in the oil, causing the speed regulation and protection parts to jam.

(2) When the synchronizer is operated manually or electrically, the load increase or decrease exceeds the specified adjustment range, which will not only cause the speed of the unit to soar after the load rejection, but also cause the pulsation of the regulating parts and sleeves, resulting in jamming and overspeed accidents.

(3) The steam quality is poor during operation, and the chemical supervision department fails to implement the ministerial standards. Long-term operation will cause jamming of main steam valve and governing valve.

(4) After major and 3HAC055437-004 DCS system minor repairs, or after 2000 hours and after the disassembly of the speed control system, the engine was started for overspeed test. The speed was not up to the standard, and the operation was improper, resulting in excessive speed rise.

3、 Measures to prevent turbine overspeed accidents:

1. In case of shutdown, the emergency governor shall be opened first to close the main throttle valve and the governing throttle valve to ensure that the generator is active, the power is zero, and the current is reversed, and then the generator can be disconnected, so that the generator disconnection time can not be delayed too long. At this time, the unit cannot be operated for a long time, and the exhaust temperature will rise under the action of air blowing, and the low differential expansion will increase, resulting in a large impact on the power grid.

2. Chemistry strictly implements the department”s steam and water standards, strengthens the supervision and test of the quality of steam and water, and prevents the unqualified quality of steam and water. The salt in the steam during operation causes the scaling of the main steam valve rod, the speed regulating valve rod, and the extraction check valve rod of each section, and the opening and closing are inflexible and jammed.

3. Chemistry should strengthen the supervision of the oil quality, implement the ministerial standards, conduct regular sampling and testing, and have reports to prevent water or sundries in the oil from causing jamming and corrosion of the regulating part sleeve.

4. The automatic main throttle valve and governing throttle valve shall be opened and closed flexibly, and the tightness shall be qualified. The automatic main throttle valve rod shall move regularly every day. Change the load by 30% every week, so as to move the governing valve and hydraulic motor slide valve. After the overhaul of the unit and before the load rejection test, the tightness test of the main steam valve and the governing valve must be carried out to ensure that they meet the technical requirements, comply with the requirements of laws and regulations and the manufacturer. When the main steam valve and the governing valve are closed separately, the maximum stable speed under the rated parameters shall not exceed 1000 rpm, but the test steam pressure shall be carried out under the rated steam pressure to obtain the main steam valve Tightness of closing of governing valve.

During operation, when the quality of steam and water is unqualified, the number and range of movable main throttle valve and governing throttle valve shall be appropriately increased, and safety measures shall be taken.

5. In case of jamming of main steam valve, governing valve and extraction check valve during operation, it shall be eliminated in time. Before elimination, safety measures shall be taken to prevent overspeed. If necessary, fast shutoff valve shall be installed. If jamming of main steam valve cannot be eliminated immediately, it shall be shut down for treatment.

6. Pay close attention to the relationship between the opening of the governing valve and the load during the regular meter reading and patrol inspection and the change of the microcomputer monitoring instrument during the operation. According to the pressure change of the governing valve, prevent the valve seat from rising or the tile from moving down, so that the governing valve cannot be closed tightly, and overspeed occurs in case of load rejection.

7. The operator should be familiar with the signs of overspeed (when the load is zero or only with auxiliary power, the sound mutation is abnormal, the tachometer continuously rises, the oil pressure rises, the vibration increases, etc.). When encountering overspeed, the operator should take decisive measures, and strictly implement the regulations to switch off and shut down to prevent the expansion of the accident.

8. When the unit is shut down for a long time, do a good job of maintenance during shutdown, and dry it once a month to prevent steam and water or other corrosive substances from entering or remaining in the steam turbine and regulating oil supply system, causing corrosion of the steam valve and regulating part sleeve.

9. In the process of starting the unit with sliding parameters, or for the unit with sliding pressure operation, the opening of the governing valve should be left with margin, and should not be too large, so as to prevent the synchronizer from exceeding the normal adjustment range or causing the speed rise during load rejection.

10. Adhere to the static characteristic test of the speed governing system. The speed governing system test of the steam turbine shall be carried out after the overhaul of the steam turbine or after the defect of the speed governing system is replaced and reset. The speed variation rate and retardation rate of the speed governing system shall meet the technical requirements. Generally, the speed variation rate is 3-6% of the rated speed, and the retardation rate shall not be greater than 0.5% of the rated speed.

11. Reasonably adjust the adjustment range of the synchronizer. The upper margin stroke should not be too large. Generally, the upper limit energy can increase the speed change rate&=(1-2)% of the margin stroke, and the lower limit energy can reduce the rated speed by 3-5%. The cam clearance of the steam distribution mechanism should ensure that the turbine can close the governing valve tightly under the hot state.

12. All additional protections of the steam turbine, such as electric overspeed protection, magnetic circuit breaker throttle, etc., shall be strictly inspected and tested to ensure that they meet the technical requirements and standards, and can be put into normal operation. They shall not be cut off at will during operation. If there are defects in the equipment that need to be treated, they shall be approved by the competent leader, and practical safety measures and technical measures shall be formulated, and they shall be put into operation after treatment.

13. After the newly installed unit and the technical transformation of the speed governing system of the unit, the dynamic characteristic test of the speed governing system shall be carried out to ensure that the dynamic runaway speed does not exceed the specified value after the load shedding of the turbine, and the turbine shall be able to maintain no-load operation after the load shedding. Generally, the runaway speed after the rated load shedding shall not exceed 8% of the rated speed, and the equipment defects found shall be eliminated in time.

14. After the overhaul of the unit, before the load rejection test, after the disassembly and inspection of the emergency governor or after 2000 hours of operation, the emergency governor test shall be carried out. However, if the oil injection test fails, the emergency governor test shall still be carried out. The overspeed test shall be carried out in strict accordance with the regulations. It is not allowed to stop for too long at high speed. The number of overspeed tests shall be reduced as much as possible. The oil injection test shall be carried out after the overspeed test to avoid affecting the action speed of the emergency governor, During the overspeed test, the speed shall be increased steadily, attention shall be paid to prevent the sudden increase of speed, and technical and safety measures to prevent overspeed shall be taken in advance.

In order to prevent the large shaft from increasing the comprehensive stress of the large shaft at the cold brittleness temperature, the overspeed test should be carried out in the hot state of the rotor along the service life of the long rotor. If the temperature requirements are not specified in the regulations, the overspeed test should be carried out when the metal temperature of the inner wall of the high pressure cylinder is higher than 150 ℃.

15. Strengthen the responsibility system and technical training of operation posts. In order to improve the technical quality and emergency response ability of operators, the following measures should be taken to select the best ones to compete for posts, so that those with high technical quality and the ability to deal with accidents can play a role in the main posts. (1) Strengthen training and strictly implement technical assessment. (2) During major and minor repair of the equipment, explain the actual construction of the speed control system components on site, so that operators can master the characteristics and performance of the equipment and avoid man-made unsafe factors. (3) Each shift shall carry out accident prediction to improve the ability to deal with accidents. (4) An anti-accident drill shall be conducted once a month, with the participation of workshop leaders and technicians, to simulate and handle accidents, and then analyze and evaluate to find out the deficiencies, so as to avoid overspeed accidents in operation and benefit everyone.

(5) The driver and crew members shall earnestly perform their duties. They must carefully monitor and inspect the equipment on duty. According to the operation mode, equipment health and weather changes, when the unit is load shedding, they should pay close attention to the speed rise, must judge accurately, handle decisively, and establish the idea of ensuring that the main equipment is not damaged, so as to ensure the safe operation of the unit.

GE General Electric DS200CPCAG1ABB 燃机卡 IN STOCK

美国NI SCXI-1162HV 光隔离数字输入模块 雄霸供应

ABB CI532V02/Exchange现货型号齐全

GE通用DS200IPCSG1ABB厂家直销

GE通用DS200DDTBG2ABB厂家直销

GE通用IS200DTAIH1ABB厂家直销

3ASC25H203 DAPC100 ABB 控制板套件 价格实惠

3BHE021889R0101 UFC721BE101 ABB模块 价格实惠

GE美国 IS200EPSMG1ABB 通讯模块 全系列

PCI-5421 NI发生器设备 两个双向通道100 MS/s

燃机涡轮控制 GE DS200ADPBG1ABB 燃机卡件

PPD113-B03 原装进口ABB控制器售后服务价格商议

ABB PP846A 触摸屏系列 PLC通讯屏 价格

ABB模块UPC090AE01 原装进口现货库存价格商议

ABB模块DSDP140B 57160001-ACX工控模块价格商议

1756-IT16 非隔离高密度温度模拟量模块

NI SCXI-1163 TTL/SSR继电器模块 SCXI-1163R 32通道光隔离板卡

NI SCXI-1160 16 个单独通道 通用继电器开关模块

NI SCXI-1126 8通道隔离频率输入模块 SCXI1126 库存

NI SCXI-1124 隔离数模转换器模块 182346E-01 5963-01-662-2253

NI SCXI-1121 4通道隔离放大器 5998-01-547-3825 SCXI1121 模块

NI SCXI-1120D SCXI-1120 8通道隔离放大器 SCXI1120D 库存

LDGRB-01 ABB I/O 模块3BSE013177R1 格雷编码器板 质保售后服务

数字伺服放大器 MMC-SD-1.3-460-D 科尔摩根 伺服驱动

NI PXIe-1086DC 直流16个混合插槽 1个PXIe插槽 PXI机箱

NI PXI-8423 板卡 PXI隔离式 PLC端口 RS485 PXI8423 库存

DDI01 ABB电源数字输入模块 价格商议实货价优

ABB DSDP140A 57160001-ACT 三个通道脉冲计数器板 模块

3HNE00313-1 ABB示教器质保实货价格商议价优售后

3BHB012961R0002原装进口ABB模块价格商议实货价优

1797-0B4D A-B 非隔离源输出模块 1797系列模拟模块

BENTLY 1900/65A 本特利电源模块 监测器 四个记录器输出

WOODWARD 机器人卡件 EASYGEN-3200

PP836 PP836A PP846 PP846A 各种型号ABB触摸屏

P4LQA HENF209736R0003 ABB 模块卡件 电气隔离 module

IS200EROCH1ABB GE 电路板 CPU处理器模块 电源模块

ABB PFEA111-65 张力控制放大器 可接ABB各种压头

ABB卡件 DSDP150 57160001-GE 输入/输出模块

GE IS200EROCH1ABB IS220PPRFH1B控制器

PP836 PP836A PP846 PP846A各系列ABB触摸屏型号优势品质好

GNT0137211P5控制器模块 一手价格 ABB原厂进口

GNT0137010R0004控制器模块 一手价格 ABB原厂进口

6007BG10000C控制器模块 一手价格 ABB原厂进口

EASYGEN-3500-5 伍德沃德 Woodward控制器 8440-1843 K 库存

GE I/O适配器板 DS200ADPBG1ABB 涡轮系统适配器模块 库存

GE 电力控制系统 IS200DTAIH1ABB 燃气轮机模块 原装 库存

Woodward 8440-1809 控制器 EASYYGEN-1500 EASYGEN-1500-55B

Woodward 8440-2085 EASYGEN-3200XT-P1 发电机组控制器

伍德沃德 8440-1884 Woodward 控制器 EASYYGEN-2500 系列 屏幕

Woodward 8440-1934 发电机组控制器 HMI Easygen-3500-5 操控屏

GE DS200TCTSG1ABB CPU电路板 库存货品

GE DS200CPCAG1ABB DC2000驱动器接口板 库存货品

GE IS200GGXDG1ABB DC2000驱动器接口板 库存货品

GE DS200IPCSG1ABB 数字信号处理器控制板 工控卡件模块

GE IS200ESYSH3ABB 电压反馈缩放板 机器人系统模块

GE DS200DTBDG1ABB 涡轮控制模块 进口工控备件

GE DS200FPSAG1ABB 通用电气模块 自动化机械备件

GE IS200DTAIH1ABB PPG处理器模块 进口电气产品

GE IS200STAIH1ABB Mark V板系列 雄霸供应

GE IS230TBAIH2C 模块

GE 369-HI-0-M-F-E-0 模块

GE HE693STP110 模块

GE IS200TREGH1BDC 模块

GE IC698CPE040、IC698CRE040 PACSystems RX7i Controller CPU

GE模块 8811-IO-DC 全新DCS/PLC系统

GE 369-LO-0-M-F-E-0-0 模块

GE VME-MB-Z004 模块

GE IS200DTAOH1ABA 模块

GE UR8FV 模块

GE模块 8913-PS-AC 全新DCS/PLC系统

GE模块 IS220PDOAH1A 美国通用备件

GE 369-HI-R-M-0-0-0-E 模块

GE IS210AEBIH1BED 模块

GE IC698CPE020 模块

GE IS200SRTDH2ACB 模块

GE HE700GEN200 模块

GE DS200RTBAG2AFB 模块

GE IS230TVBAH2A 模块

GE VMIVME-7658 模块

GE 469-P1-HI-A20-E 模块

Company advantage service:

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

All kinds of module card driver controller servo motor servo motor embedded card wires and cables Power module control module is applicable to steel, hydropower, nuclear power, power generation, glass factory, tire factory, rubber, thermal power, paper making, shipping, navigation, etc

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts